- Home

- Facilities listing

- Engineering project workshop

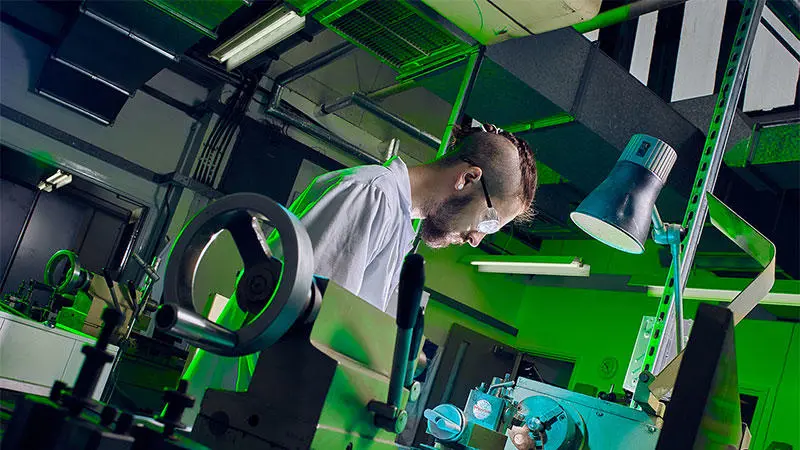

Engineering project workshop

The workshop is purposely set out to accommodate students and allow them to be taught mechanical engineering, and progress with any ongoing project work.

About the Engineering project workshop

The engineering project workshop is set out to mirror an engineering plant. The lathes and mills are separate from the work benches, allowing sixteen students to work in a safe manner.

The area is used for undergraduate teaching and project work by both undergraduate and postgraduate students. The workshop is also used for research work, where mechanical work is needed.

The workshop is equipped with industry-standard equipment, giving students the opportunity to work in a ‘real world’ environment. The equipment is also used by qualified staff when complex projects need to be manufactured for students who are not on an engineering based unit.

Technical maintenance of any mechanical piece of kit from around the University is produced, to aid in the smooth running of the teaching curriculum.

Equipment

- Marlco hydraulic press

- Keetona sheet metal folder

- Keetona sheet metal roller

- Bridgport vertical milling m/c

- Polylab injection moulding demo unit

- Harrison M300 lathe 13"

- Harrison M300 lathe 13" with digital readout

- Harrison T300 lathe

- Myford lathe

- Myford super 7 lathe

- Startrite horizontal band saw H250M

- Bandfacer linisher

- RS 10" band saw

- Herbert high-speed drill

- Startrite bandsaw

- Jones & Shipman surface grinder 540

- Abaroga Maskiner pedestal grinder P312

- Denbigh fly press No 4

- Bridgport vertical mill series 1

- NI pedestal grinder 10"

- Hitachi pedestal grinder 6"

- Shadow graph PJ2500

Courses that use this facility

- BEng (Hons) Electronic Engineering